INFORMAÇÕES TÉCNICAS

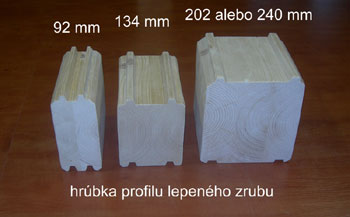

- Rustic solid wood profile thickness 28, 44, 64, 68, or 92 mm

- log profile glued thickness of 134 mm

Glued log profiles are used in larger thicknesses log cabins, or when we have a log cabin on both sides

open ceiling. That means no thermal insulation, or other tile, of course it is not a requirement. Glued

log cabin is composed of two or more blades, which you will find are stuck in one piece.

Radius profiles used zrubov

|

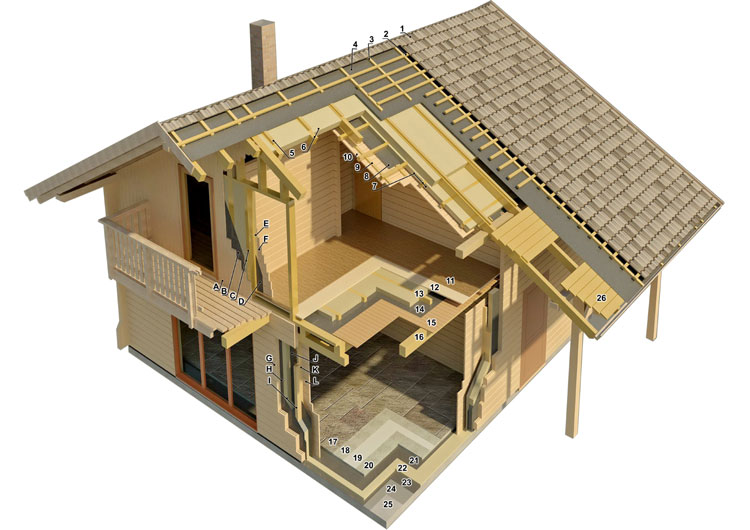

Log construction-standard composition of the walls of houses

|

|

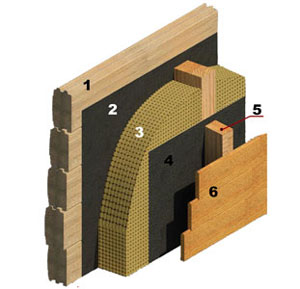

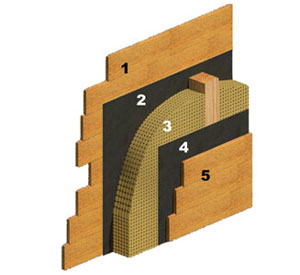

| External wall Rustic: 1 - log profile solid wood thickness 68 or 92 mm 2 - vapor permeable film 3 - insulating fries (razor), thermal insulation thickness 140 mm 4 - vapor barrier 5 - wooden grid, air gap thickness 28 mm 6 - wood paneling thickness 19 mm or 12.5 mm thick plasterboard |

Walls - lattice structure: 1 - wood paneling thickness of 19 mm or 12.5 mm thick plasterboard 2 - vapor permeable film 3 - insulating fries (razor), thermal insulation thickness 100 mm 4 - vapor barrier 5 - wood paneling thickness of 19 mm or plasterboard thickness 12 5 mm |

|

|

| Ceiling: 1 - Wooden 2 - backing sheet 3 - OSB 4 - Impact sound insulation 5 - OSB 6 - Insulation prisms 7 - Insulation 8 - Vapour 9 - ceiling P + D 10 - supporting beams |

Roof: 1 - Roof laths 2 - venting lath 3 - Water vapor permeable sheet 4 - Compensatory panicles 5 - Supporting structure (rafters 92 x 170 mm) Insulation 6 - Barbecue + thermal insulation 7 - Vapour 8 - venting grid thickness 28 mm 8 - ceiling facing 19 mm |

External wall Rustic - COMPOSITION- Log solid wood profile thickness 68 or 92 mm |

|

|

Detail combinations for fastening drywall and ceramic tiles |

Rustic perimeter wall with cork insulation

|

- Log profile - exterior 68 or 92 mm |

Dvojstienky choice of a combination of log profiles with a thickness of 44, 68 and 92 mm

Log construction-standard composition of the walls of houses

|

Piece truss: |

Types of ceilings: |

Floor structure on the ground: |

|

Composition of the wall below the shield: |

Types of exterior walls: |

Prismatic construction - Standard construction of the walls of houses

|

|

| Types of building envelope: 1 - 15 mm OSB 2 - insulation fries (razor), thermal insulation thickness of 160 mm 3 - vapor barrier 4 - a wooden pallet, the air gap thickness of 28 mm 5 - wood paneling thickness of 19 mm or 12.5 mm thick plasterboard |

Track walls - lattice structure: 1 - wood paneling thickness of 19 mm or 12.5 mm thick plasterboard 2 - vapor permeable film 3 - insulating fries (razor), thermal insulation thickness 100 mm 4 - vapor barrier 5 - wood paneling thickness of 19 mm or plasterboard thickness 12.5 mm |

|

|

| Piece ceiling structure: 1 - Floor 2 - backing sheet 3 - OSB 4 - Impact sound insulation 5 - OSB 6 - supporting beams - nepohľadové 7 - Insulation 8 - Vapour 9 - Grid 10 - ceiling P + D |

Roof: 1 - roof slats 2 - venting lath 3 - vapor permeable sheet 4 - leveling boards 5 - a supporting structure (rafters 92 x 170 mm) Insulation 6 - grid with thermal insulation 7 - vapor 8 - venting grid thickness 28 mm 8 - ceiling facing 19 mm |

The design of the house with the columnar structure

Thermal resistance and heat transfer coefficient

|

When using technology to renewable energy can be achieved by building energy class: A As evidenced by our building energy performance certificate. |

insulation

Production

|

Production Our products are manufactured on the most modern high-performance, fully automated and computer controlled HUNDEGGERK2 line, customers can guarantee high quality and short delivery times. It is a fully automated top line for production of carpentry and joinery frames and trusses for houses. Production hall in the village of Kriva is focused on the production of doors and windows in our log buildings. New technology has enabled us to quickly manufacture and arbor, garden cottages and sofas and many other accessories made of wood. |

Carpentry joints zrubov

|

Lapping with overlap |

dovetail joint |

prismatic joint |

Manufacture roof trusses to measure

Roof trusses are structures which must be carried out by experts as their production and installation requires great skill, especially for complex hedge. The great advantage of our company is projecting roof at the latest 3-D programs and subsequent production of the fully automated production line. This allows us to make complex ground plan with traditional beamed roof systems and prisons and brace. Trusses, possible delivery mainly open ceiling trusses made of solid wood or using prisms glued laminated spruce wood. For the production of frameworks we use dried spruce. Our company is a member of the Association of Wood Processors.

CERTIFICAÇÃO DO PRODUTO

Todas as Construções de Madeira da Woodcasa possuem certificação.

Certificado de madeira Pré-fabricada DREVODOM ORAVA

A madeira foi tecnicamente testada e ensaiada no Testing Institute da Construção, em 23 de agosto 2011, em Bratislava, de acordo a com a Lei. 90/1998 "Coll. Produtos de Construção", tendo sido aprovada e tendo obtido o Certificado Conformidade SK04 - ZSV - 1524. A Empresa Drevodom Orava é membro pertencente da Associação de Processadores Madeira da República da Eslováquia.